For most businessmen, enameling is an obscure craft. But Scott Ellis has family connections to the industry, and he understood its appeal–and its potential as a business opportunity. His online business, e-namels.com, started as a clearinghouse for surplus enamels, but has expanded to carry an extraordinary range of foreign-made, specialty, and out-of-production enamels. Here, as part of our Tools and Supplies series, Ellis discusses the evolution of his business and how he plans to make life easier for the production artist.

Scott Ellis with some of his stock of out-of-production enamels that he sells on his website, http://www.e-namels.com/.

Center for Enamel Art: How did you get started with your business?

Scott Ellis: I went to college right at the time everyone was coming online, in the ’90s, and that had a big influence on me. I always knew I wanted to do something in the online space, if not full-time then part-time; start a venture of my own. My uncle Tom Ellis has worked at Thompson Enamel for 35 years, so I’ve always had some familiarity with enameling, and I’ve always found it interesting because I’m not an artist. So I had a mild interest in it all along.

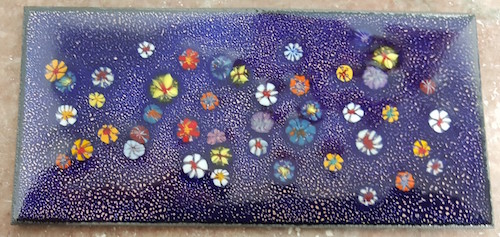

Floral wafers of the sort supplied by Ellis’ father.

My dad, whom I’m very close to, is also a supplier. He makes what are called floral wafers, a glass product that is kind of like the millefiori of Italy, but softer. In 1996, a large badge maker switched from using lead-bearing enamels to lead-free enamel. We drove to Chicago and picked up a large amount of lead-bearing enamels that were given to us for free, which my dad then used to make wafers. And then we thought, we have all this enamel here, how can we sell it? This was about the time that online commerce was really expanding, and I was able fairly easily to build a website and begin selling the enamel. Then people started calling me, asking for specific colors. I realized fairly quickly that out of 400 colors, I didn’t have many of the popular colors. So I started networking. Someone would call Thompson, trying to sell their old enamel, and I would make the purchase.

CEA: Where were these coming from? Companies that had gone out of business?

SE: No, enamelists that had retired, or who had died and whose families were selling the inventory. I also bought things off Etsy, eBay. I call myself the ‘American Picker of Enamels.’ I will show up to your door to buy your enamels and offer you a fair price for it. The really lucky thing, the day that really changed my life, was when a large badge maker in Canada called me to say that he had 1600 pounds of enamels, sitting on a pallet in a corner. It had been his dad’s. I’m thinking, no way I can afford to buy all of those. I said, “What were you looking to get out of it?” And the guy said, “It’s just taking up space. If you’ll pay to put it on a truck and ship it out of here, you can have it.” So that was really a great jump start. There was a lot of variety and color there, and it really helped propel my business.

W.G. Ball enamels from England in Ellis’ stockroom.

CEA: How did your business evolve from simply selling Thompson leaded enamels to selling a large variety of enamels and enameling supplies? Some of the products you sell, like Blythe enamels, aren’t available directly from the manufacturer and must be bought through a supplier like your company.

SE: In the making of the wafers, we found that lead-free flux couldn’t replace the lead-bearing flux we were running out of. Guido at Thompson told us about the Blythe enamels from England which Thompson used to carry. Milton Bridge, a UK enamel manufacturer, bought the Blythe formulae. Through communications with people at Milton Bridge I discovered C-10 flux which worked beautifully for us. After that, around 2009, we started exploring all the UK enamel manufacturers. We have the whole Schauer line that was originally made in Austria and is now being made in the UK. We have the whole MB and Blythe lines of enamels as well. I’ve gone from selling a product that’s no longer made, where I would scratch my head at night to figure out what I would do when I ran out of it, to having a steady supply of MB, Schauer, and Blythe.

CEA: So that’s great for domestic buyers because they don’t have to buy from England, from a giant industrial supplier.

SE: Right. Milton Bridge is a distributor and won’t sell directly to consumers. They don’t take little orders. Unless you want 10 lbs of enamel, and most hobbyists don’t, you can’t buy from them. So I added that line. And I added the Thompson’s lead-free line. I worked out a distributorship from W.G. Ball, another lead-free manufacturer in England, which makes a beautiful line of enamels as well. My whole goal was to get as many lines of enamel as I could in one location. One store, one place to shop.

CEA: I noticed you also carry the Ninomiya.

SEA: Yes. They make hands down the most beautiful leaded enamels today by far. Most consistent. There are two companies there — Ninomiya, and Nihon Shippo. People here know them as “Japanese enamels” they’ve been kind of interchangeable, but it’s actually two manufacturers. I’ve always scratched my head as to how can I buy this enamel. It’s a small company. They don’t have a website. They don’t speak English. I tried everything I could to purchase from these guys. Then one day in 2014 I got a call from the owner of Enamel Emporium, a reseller of the Ninomiya and other Japanese enamels and enameling supplies in Texas. He was closing up shop and moving back to Japan. I bought his inventory and he is now my English speaking contact in Japan. I’ve been able to have that line of enamels on my website for the last year and a half.

Sunshine painting enamels, which Ellis packages in a kit for enamelists.

The most recent line I’ve added is Sunshine painting enamels. Sunshine is owned by a U.S. company, but because it is lead-bearing, it is manufactured in Germany. These painting enamels are a great product, but they must be bought five kilograms at a time, much more than enamel artists would need. I wanted to package them in a way that made them accessible to artists, so I created a kit with 10 grams of color, a binder and very nice packaging. Ten grams will last a very long time. You take a little scoop of the painting enamel, add a binder to it and you’re painting with it. Gillie Hoyte Byrom from the UK used the Sunshine colors in the workshop she taught at the last Enamelist Society conference in Boston, which was hugely popular.

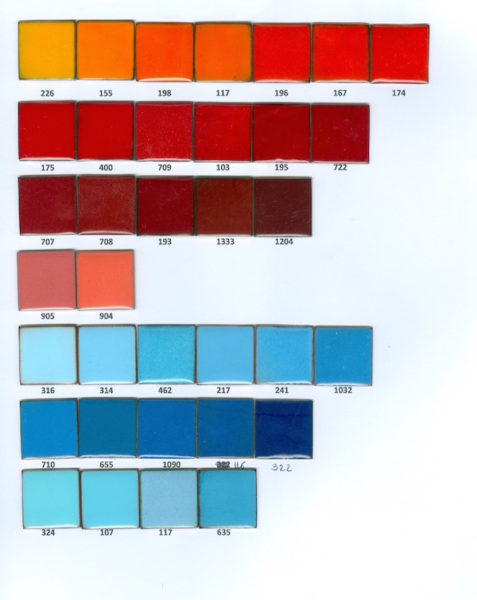

Ellis prepares color charts of all of the enamels he sells, available at http://www.e-namels.com/.

CEA: You obviously have some technical understanding of enamels also.

SE: I’m learning every day. And if you’re an enamelist you’re always learning. There are a lot of good resource books. Bill Helwig said it best: “It’s not that the enamel didn’t work. It didn’t yield the results you were expecting.” What he meant was, if I put an opaque in the furnace and I overfire it accidentally, it’s going to turn transparent. It might give me a beautiful color. Different colors work differently when they are layered than when they are used separately.

CEA: Who are your customers?

SE: Hobbyists, artists, people making production jewelry, people making high end expensive jewelry. I’ve sold to just about everybody in the industry. I’ve sold to badge-makers, so I do have some industrial clients as well. I have a lot of international clients. England, Australian, Netherlands. Artists buy ounces and industries buy pounds.

CEA: So do you see trends? Is business booming or shrinking?

Ellis has taught himself to spin copper bowls and forms to sell to artists and makers. The process begins with discs cut on a circle shear.

SE: My business has grown every year for eight years now. It’s grown because I have the luxury of taking everything I have and putting it back into the business. This is a part-time job for me. A couple of years ago I ventured into metal spinning. It’s a dying art. I taught myself how to do it through trial and error, and through talking to other metal spinners. So now I offer a full line of spun bowls and spun plates. I use handmade mandrels for the forms. Some are made of wood and steel. I also work with a tool-and-die guy who makes some mandrels out of aircraft grade aluminum.

Using a mandrel and an aluminum form, Ellis shapes the disc into a bowl.

I also continue to make my website a “visual resource.” I try to fire samples of all enamels we carry, on multiple metals. I want anyone to be able to quickly access our website and compare colors. I am always happy when someone shares their sample firings with me and allows me to put their images on my website.

CEA: Do you have plans to carry firing tools?

SE: Not at the moment — I will leave that to Allcraft and Rio Grande.

CEA: How much do you have to publicize your business?

SE: I try to optimize for every search engine, use Google keywords. I sponsor an ad in the Enamelist Society newsletter. It’s a large community, but not a huge community. So I try to be very smart about where my advertising dollars go.

CEA: Do you work alone?

SE: For the most part, my dad helps out some and is very busy with his floral wafer business.

CEA: You don’t have any serious competitors that have the range that you do.

SE: Rio Grande outsells me on unleaded enamel probably 100 times to one, but there is no one that has as many lines as I do. The world’s largest supplier of vitreous enamel: That’s my motto.

CEA: What’s in the future?

SE: The future for me is working collaboratively with artists themselves.

CEA: What do you mean by that?

One of the final forms, handspun by Ellis.

SE: For example, instead of someone hand-sifting a hundred units, I can spray those with liquid enamel for you and save you the time. I can cut the copper shapes with dies that I make for you. I can source the entire product for you. You may want to put a decal on it, put your own design on it. For example, we help a company that makes cufflinks. We make the base of the cufflink, they put it in a bezel, personalize it with someone’s initials, and sell it as a finished product. We help them make that product. I want to expand that. I want to expand more of a one-to-one relationship with my clients, where I can, but I want to use technology to do that.

Another example: Next year I will have a water-jet. There is a company that came up with a desk-top water-jet, which costs less $10,000. It was a year-long wait to buy one, but mine will be delivered in August. So someone that is going about making a semi-unique piece, spending two to three hours cutting it out with a saw — we can design that out on CAD, put that into the software of our water jet, and cut it out in 20 minutes. And replicate it again and again.

CEA: There’s a market for that with jewelers today.

SE: You look at the shapes that are out there today, Thompson cuts out most of the shapes in the industry. Old technology. Dies, punches. This process is effective but not flexible, and it is getting harder to find a good tool and die shop in the United States. Plus, making dies is not cheap. So if you only need a few pieces of a certain design, the punch and die process is not cost effective. With a water jet, we can make new shapes and customize, relatively inexpensively as compared to a short run tool and die process.

CEA: What is your day job?

SE: I work in the auto lending industry, as a manager of a strategic account team for Cox Automotive.

CEA: Would you like it if e-namels.com could be your main business?

SE: I would love for e-namels.com to be my main business. That is my ultimate goal.

CEA: So what are the biggest challenges?

SE: There’s only so much enamel out there to be sold. As we said, the enamel community is large, but not huge. And you don’t need a lot of enamels if you are working small. So I have to figure out ways to branch out, to be more collaborative, to help my customers make their product and make money themselves. The water-jet technology is the beginning of that. What else can I do that is in the industry, that complements what I already do today?

One of Ellis’ bowls, enameled by his uncle, Tom Ellis of Thompson Enamels.

CEA: Judy Stone, the founder of the Center for Enamel Art, has talked about the importance of encouraging artists to work large, of bringing back industry-artist relationships.

SE: I’m always open to opportunity. I’ve learned in business over the years that you should never say somebody has a bad idea. The guy who started FedEx, he wrote his college senior thesis on an overnight delivery service and his professor gave him an F on it. Today we use overnight delivery and we don’t think twice about it. I’m not saying enameling is going to have a breakthrough that way, but it’s all possible. I’m always willing to listen to someone’s ideas.

Recent Comments