This is the seventh in a series of guest posts by the enamel artist Kat Cole. This post previously appeared on her blog.

Grey panels

By the end of my first day at KVO Industries my crate had still not arrived and I was beginning to panic. My time was limited to this one week in Santa Rosa, and if the crate did not arrive and I did not get the work done, I would have no option but to pack it back up and send it back home to Dallas unfinished. And, while I was renting time and space at KVO, I still had to be courteous of the workers’ spraying and firing schedule.

The memorial panels in process

The week I was there was a busy one. They had just begun on a big order for a large number of blank grey panels that would be used for changeable vinyl signage at a university. Also that week, they were working on a series of prototype photo collage panels for a funeral home that would be mounted on headstones. The use of durable enamel signage for grave makers was not a use that had occurred to me before, but turns out to be a growing market.

I began my second day at KVO with still no crate, and spent the morning calling the freight company and working on samples. I would be using a combination of Thompson Enamels and KVO’s in-house mixed enamels. I had worked with this combo at home, but knew you could never do too many samples, and something new always comes up working in a new space.

To clean the surface of small parts, they taught me to take old liquid enamel and rubbed it all over the piece, allow it to dry then brushed it off. Worked like a charm, all oils and dirt removed.

Finally midday my crate arrived and work would really begin. The panels would need to be sanded in the areas where rust had begun to form and a few needed additional tabs added for hanging. The interior of the KVO kiln is eight feet long and seven feet high and three feet deep. There are hanging tracks on both sides so during high production they do not have to wait for a load to cool and be unloaded before doing the next firing. By the end of my second day the panels were washed and ready to begin work.

Finally midday my crate arrived and work would really begin. The panels would need to be sanded in the areas where rust had begun to form and a few needed additional tabs added for hanging. The interior of the KVO kiln is eight feet long and seven feet high and three feet deep. There are hanging tracks on both sides so during high production they do not have to wait for a load to cool and be unloaded before doing the next firing. By the end of my second day the panels were washed and ready to begin work.

Panels going into the parts washer for a good cleaning

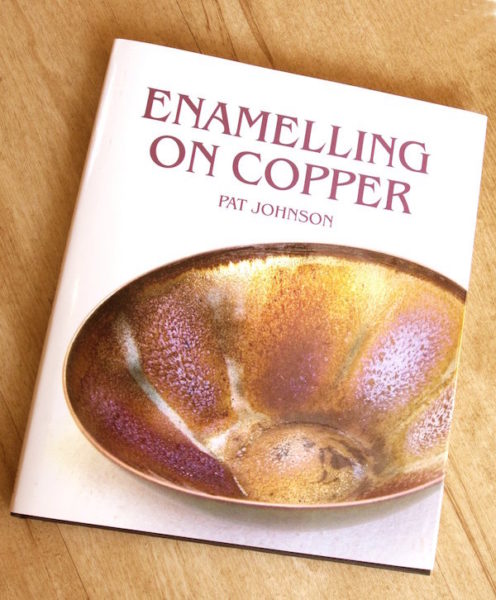

Enamelling on Copper by Pat Johnson

Enamelling on Copper by Pat Johnson

There is no shortage of things to get done with a project of this size, I am realizing. Once the work was crated up and safely on its way back to Dallas, I spent a few extra days in California with my husband, a brief bit of down time. When I returned,

There is no shortage of things to get done with a project of this size, I am realizing. Once the work was crated up and safely on its way back to Dallas, I spent a few extra days in California with my husband, a brief bit of down time. When I returned,  The process of enameling at KVO was a bit of a fast – slow – slow pace. I would have windows of time that I would have my spray gun ready to hop into the spray booth and get a coat on during the workers’ breaks. Their workday would usually begin at 6am and go until 3pm. I got into the habit of getting there around 7am, enjoying the time just being in the space and listening to the guys chat.

The process of enameling at KVO was a bit of a fast – slow – slow pace. I would have windows of time that I would have my spray gun ready to hop into the spray booth and get a coat on during the workers’ breaks. Their workday would usually begin at 6am and go until 3pm. I got into the habit of getting there around 7am, enjoying the time just being in the space and listening to the guys chat.

Finally midday my crate arrived and work would really begin. The panels would need to be sanded in the areas where rust had begun to form and a few needed additional tabs added for hanging. The interior of the KVO kiln is eight feet long and seven feet high and three feet deep. There are hanging tracks on both sides so during high production they do not have to wait for a load to cool and be unloaded before doing the next firing. By the end of my second day the panels were washed and ready to begin work.

Finally midday my crate arrived and work would really begin. The panels would need to be sanded in the areas where rust had begun to form and a few needed additional tabs added for hanging. The interior of the KVO kiln is eight feet long and seven feet high and three feet deep. There are hanging tracks on both sides so during high production they do not have to wait for a load to cool and be unloaded before doing the next firing. By the end of my second day the panels were washed and ready to begin work.